Our Process

Raw materials are controlled through a proper Quality analysis which is essential to achieve best in class products.

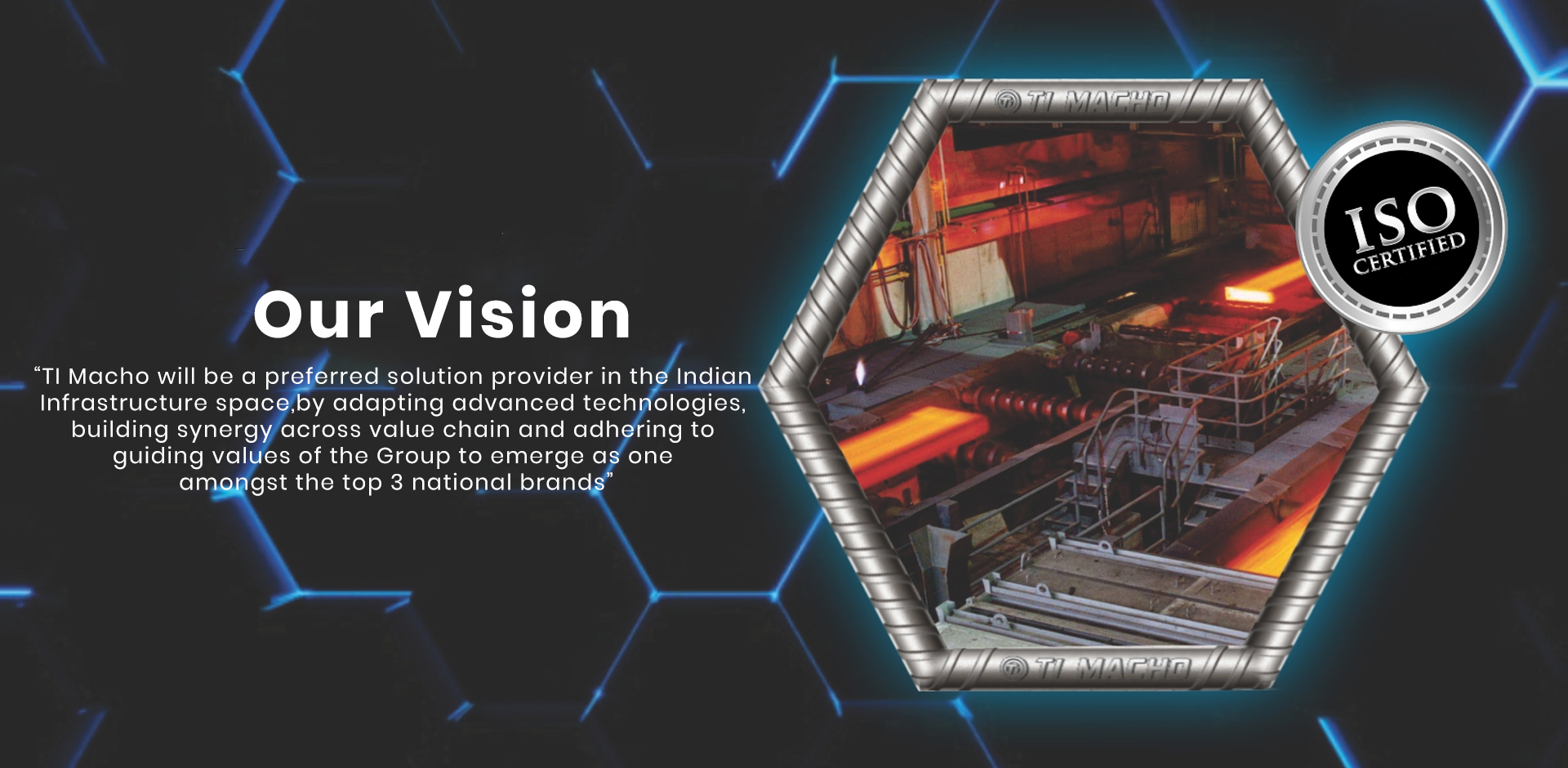

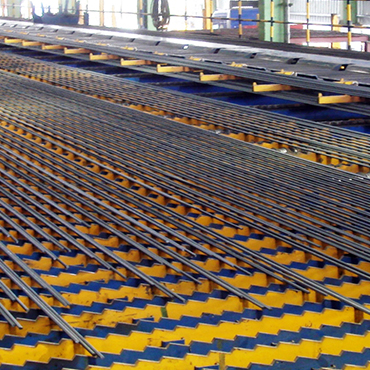

Steel billets are hot rolled and are subjected to Thermo-Mechanical Treatment.

High performance TI MACHO TMT Bars are manufactured through a unique patent quenching process post hot rolling

This results in optimized- Higher Strength & Ductility

- Longer life

- Higher Shock Resistance

- Higher Corrosion Resistant